- Responsibility

-

Responsible leadership

-

Social opinion leader

-

Responsible procurement operations

-

Research and development

-

Safety

-

Good work community

-

Shareholder value

-

Supply of electricity in Finland and climate impact

-

TVO as a company

-

Environment and climate

-

Environmental management

-

Environmental program 2019–2021

-

Results of the environmental program

-

Climate-friendly electricity

-

Environmental impacts

-

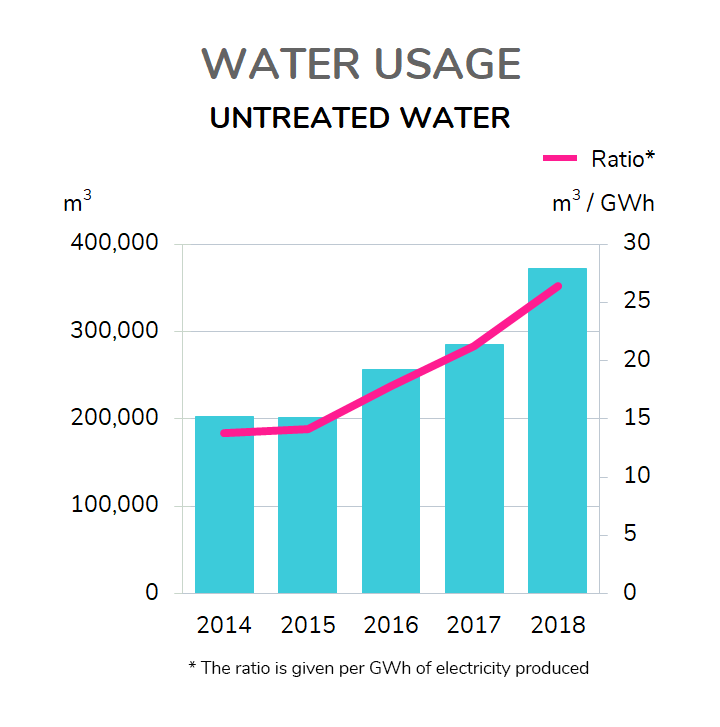

Cooling water

-

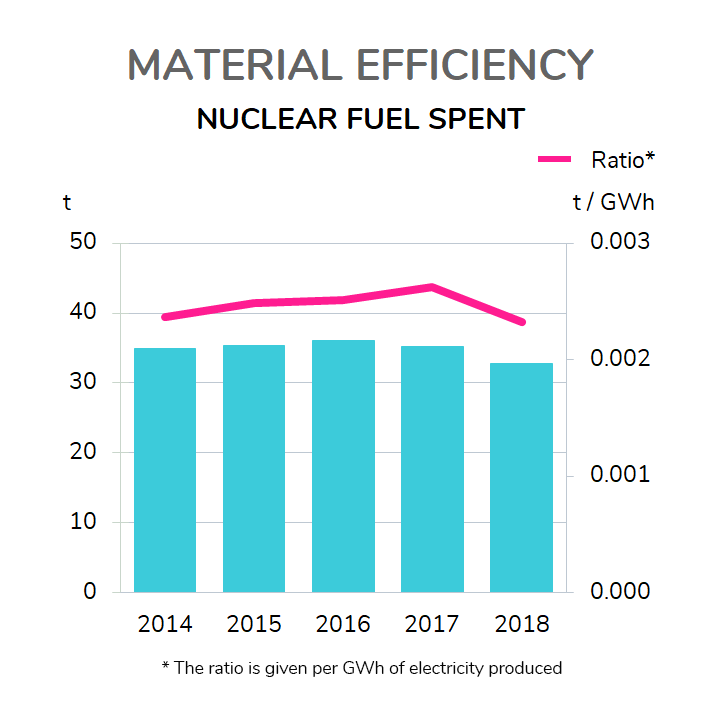

Raw materials and material efficiency

-

Production and energy efficiency

-

Emissions to the air

-

Emissions to water and soil

-

Waste

-

Environmental research and biodiversity

-

Cooperation with the authorities

-

Nuclear waste management

-

-

Responsibility reporting

- Governance

-

General

-

Shareholders' meeting

-

Board of Directors

-

Board committees

-

Committees and steering groups assisting the management

-

President and CEO

-

Management Group

-

Auditor

-

Remuneration

-

Insider administration

-

Disclosure policy for investors

-

Internal control and risk management

-

TVO Board of Directors in 2018

-

TVO Management Group in 2018

-

Organization

-

- Report of the Board of Directors

-

Main events in 2018

-

Operating environment

-

TVO as a company

-

Financial performance

-

Financing and liquidity

-

Share capital

-

Administrative principles

-

Administrative bodies

-

Regulatory environment

-

Risk management, major risks and uncertainties

-

Pending court cases and disputes

-

Nuclear power

-

Coal power

-

Research and development

-

Acquisitions of tangible and intangible assets and shares

-

Responsibility

-

Group personnel and training

-

Subsidiaries and joint ventures

-

Major events after the end of the year

-

Prospects for the future

-

Proposals to the Annual General Meeting

-

- Financial Statements

-

Key figures of TVO Group

-

Key figures of Teollisuuden Voima Oyj

-

TVO Group financial statements

-

Consolidated income statement

-

Consolidated statement of comprehensive income

-

Consolidated balance sheet

-

Consolidated statement of changes in total equity

-

Consolidated cash flow statement

-

Notes to the consolidated financial statements

- 1 General information on the Group

- 2 Accounting policies

- 3 Segment reporting

- 4 Work performed for own purpose

- 5 Other income

- 6 Materials and services

- 7 Personnel expenses

- 8 Depreciation and impairment charges

- 9 Other expenses

- 10 Finance income and expenses

- 11 Income tax expense

- 12 Property, plant and equipment

- 13 Intangible assets

- 14 Investments in joint ventures

- 15 Book values of financial assets and liabilities by categories

- 16 Loans and other receivables

- 17 Investment in shares

- 18 Cash and cash equivalents

- 19 Inventories

- 20 Derivative financial instruments

- 21 Equity

- 22 Interest-bearing liabilities

- 23 Trade payables and other current liabilities

- 24 Assets and provision related to nuclear waste management obligation

- 25 Obligations and other commitments

- 26 Related party

- 27 Financial risk management

- 28 Changes in accounting principles

- 29 Events after the balance sheet date

-

-

Parent company's financial statements

-

Parent company's income statement

-

Parent company's balance sheet

-

Parent company's cash flow statement

-

Notes to the parent company's financial statements

- 1 Accounting principles

- 2 Turnover

- 3 Work performed for own purpose

- 4 Other income

- 5 Materials and services

- 6 Notes concerning personnel and members of administrative bodies

- 7 Depreciation and impairment charges

- 8 Other expenses

- 9 Financial income and expenses

- 10 Appropriations

- 11 Non-current assets

- 12 Investments

- 13 Inventories

- 14 Current receivables

- 15 Equity

- 16 Distributable equity

- 17 Non-current liabilities

- 18 Debts due in more than five years

- 19 Current liabilities

- 20 Commitments

- 21 Derivative financial instruments

- 22 Series of shares

- 23 Carbon dioxide emission rights

-

-

Proposals to the Annual General Meeting

-

Signatures for the report of the Board of Directors and financial statements

-

Auditor's report

-

Financial information in 2019

-

Parent company's financial statements